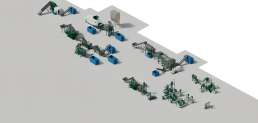

Flexibility and performance:introducing our turnkey plants.

Turnkey plants

We design and build turnkey plants for the processing of metal waste.Our know-how is rooted in 30 years of experience, initially working in the recovery of waste, then designing and marketing our complete recycling solutions.We know how to be at your side to meet your business goals. We analyse together with the customer the scrap to be processed and the output to obtain. We study the ideal logistics, assessing the flexibility of the plant and the overall return on investment, providing technical training and advanced monitoring instruments.

Flexibilityand performance:introducing our turnkey plants.

Turnkey plants

We design and build turnkey plants for the processing of metal waste.Our know-how is rooted in 30 years of experience, initially working in the recovery of waste, then designing and marketing our complete recycling solutions.We know how to be at your side to meet your business goals. We analyse together with the customer the scrap to be processed and the output to obtain. We study the ideal logistics, assessing the flexibility of the plant and the overall return on investment, providing technical training and advanced monitoring instruments.

A complete and efficient treatment cycle

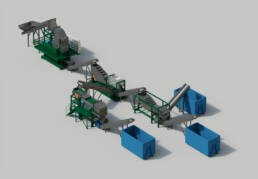

Shredding and pre-machining of metal scrap

The first recycling step is dedicated to the pre-machining and volumetric reduction of waste through shredding. The conveyor belt moves the pre-treated material to the manual sorting station. The station can include a soundproofing cabin, a suitable accessory for the operator’s comfort at the workplace.

- Shredder

- Soundproofing cabin

Grinding of scrap

The material goes on to the grinding area which, depending on customer requirements, can include a stationary hammer mill or a mobile hammer mill. Our configurations are modular and can make use of the following separation systems: extraction system, zig-zag separation system, vibratory sieve with drum, dynamic shake and eddy current.

- Drum vibratory sieves

- Dynamic Shake

- Eddy Current

- Extraction system

- Zig zag separation system

Concentration

This step can be necessary for the concentration of previously crushed outputs, for separation from specific alloys, individual metals or from inerts. The treatment system includes modular systems such as rotary sieve and X-ray separation plant. The latter can be supplied with a specific compressed air circuit.

- Rotary sieve

- XRay separation system

Refining plant

For the End-of-Waste treatment of a wide range of waste, even in presence of considerable percentages of wear-causing steel and inerts. It includes patented refiner hammer mills and performs a mechanical treatment cycle, completely in-line and fully automated. The metal granule output is impurity free, potentially classifiable as secondary raw material.

- Pre-refining hammer mills

- Refining plant

Plant with optical sorter

A plant with an optical sorter could be used at the end of the refining cycle for thorough high quality sorting. The loading feeder automatically manages the infeed flow, while the sorter is supplied complete with electric panel and compressed air circuit.

- Loading feeder

- Optical sorter

Control and supervision software

Panizzolo software allows you to manage and monitor the plant from the machine or remotely. This instrument allows customers to always have a clear view and in real-time, not only of the individual parameter, but of the production trend of the entire plant and of its components.

- Panizzolo Software