Our refining plant

Excellent outputs, impurity-free and classifiable as Secondary Raw Material.

it's time to maximizethe value of metals

Why choose our refining plant

Every year tons of waste still rich in copper, aluminium and brass is sent to the landfill or exported due to the large amounts of wear-causing steel and inerts which often nullify the profitability of the process. Traditional plants and solutions currently on the market are in serious difficulty to find an effective solution to the problem, while the Panizzolo refining plant is capable of profitably recovering even the smallest quantities of metal, mechanically and with completely in-line treatments.

Strengths

Fields of application

The main waste treated by the plants is mixed metal fluff, WEEE fluff, car-fluff, electronic circuit clippings, alucobond, aluminium caps and deironised copper. Fluff is waste from flotation plants or mixed metal grinding and contains a large amount of copper, aluminium, steel, glass and cement dust.

Grinding and size

The first step is carried out by the RAF-M mill, ensuring a reduction ratio of 5:1 and accepting an infeed size of 0-30 mm. The second step is carried out by the RAF-F mill, ensuring a reduction ratio of 4:1 and accepting an infeed size of 0-8 mm.

End-of-Waste cycle

At the end of the treatment cycle, almost all non-marketable byproducts are eliminated, retrieving only the clean metal granules, classifiable as secondary raw material.

Avoids drops in production

The processed metal scrap can cause significant wear, thus undermining the actual yield of processing over time. On the other hand, Panizzolo refining plants are specifically designed for even wear of the individual components, so as to avoid breakage or sudden drops in production. using the special castings also ensures longer service life of hammers and armours.

Flexibility and efficiency

The technologies installed feature the highest reduction ratio on the market and a variety of adjustments, so as to easily change the type of infeed waste.

Completely in-line treatment

Considerable reduction of management costs thanks to Panizzolo software. It autonomously controls the treatment cycle, excluding direct interventions by operators and features a specific session for customising the parameters.

Refiner hammer mills

Panizzolo Recycling refining plants stand out due to the innovative RAF-M granulator and RAF-F turbine hammer mills. These feature patented elements that make them highly efficient and productive, capable of simultaneously processing waste with steel, plastic, glass and cement dust.

The recycling logic and the special castings, designed jointly with the University of Padua, allow for even wear of the individual components, guaranteeing longer service life and avoiding sudden drops in production.

Dedicated sorting systems

Specific sorting systems of the ground material are used in Panizzolo refining plants. These are easy to perform modular technologies, designed to work in-line and structured for easy maintenance. Panizzolo supplies different dedicated equipment depending on the type of infeed waste and the type of treatment.

Densimetric tables

TDP series densimetric tables designed directly by Panizzolo to optimise air flow, to maximise sorting performance and to provide a simple and fast access to the components for periodic inspections and maintenance.

The machinery performs dry sorting of granular material through a combination of air flow and vibratory movement.

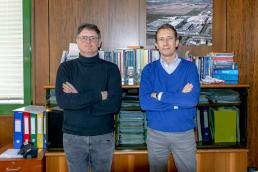

Stories of satisfied customers

In a constantly moving market, it’s good to always stay up to date.

Follow the news of the sector and the Panizzolo columns.